Increasing concerns over the detrimental transfer of invasive marine species across the world’s oceans through the transport and disposal of ballast water by large vessels have prompted the

International Maritime Organization and the

United States Coast Guard to impose regulations for the treatment and discharge of ballast water. Already in force in U.S. waters as of January 1, 2015, universal ratification is expected by early 2016.

An estimated 65,000 ships over 400 gross tons must be fitted with approved Ballast Water Treatment Systems, “BWTS”, within the next 5 years. The approved systems must disinfect the seawater without adding any toxic elements to the discharged water.

Global Water Intelligence estimates that the average cost for each system is more than $750,000 and the total cost to outfit every vessel will be about $50 billion.

Thousands of organisms carried in ballast water can cause severe ecological damage resulting in large economic burdens and even human health risks. Two examples of harmful consequences are:

Mnemiopsis leidyi

Mnemiopsis leidyi, a comb jelly (similar to a jellyfish) feeds on anything smaller than itself that gets stuck to the sticky lobes near its mouth, especially zooplankton. It was probably introduced via ballast water from New England (USA) into the Black Sea. In its new environment,

Mnemiopsis has no natural predators and has outcompeted native species for food. As a consequence, the once profitable anchovy fisheries in Russia and Turkey have almost disappeared.

One of the most widely known invasions in the United States is that of

zebra mussels into the Great Lakes. These organisms grow on almost any structure, forming large clumps of mussels that can clog water intake pipes and damage or impair other structures. Periodically these organisms need to be removed from pipes and other structures, and that requires time, money, and sometimes-specialized equipment.

The U.S. Coast Guard and the IMO have not yet approved any permanent Ballast Water Treatment Systems but are expected to begin approvals by the end of 2015 and have already

approved 9 systems for temporary use as of April 2013. As expected with a $50 billion windfall opportunity, the competition is stiff with over 55 different systems currently offered and awaiting permanent approval. Ultraviolet (UV) disinfection in combination with filtration is the most commonly used technology, followed in second place by electro chlorination. Electro-chlorination has historically been the preferred choice for use in larger vessels because it is believed by some to be more effective with larger flows compared to UV.

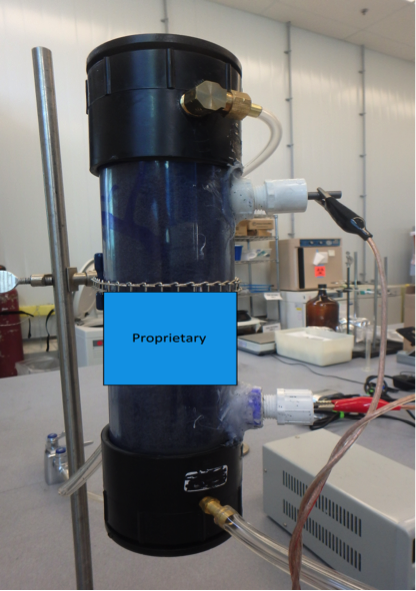

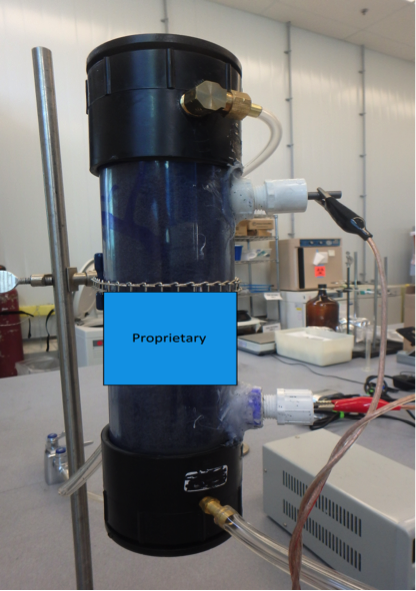

Current systems offered are large, complex and expensive. As an example see this image of a BWTS by Cathelco.

There are many examples of water treatment technologies that work well. However, the cost (both Op-X and Cap-X) is most often so high that industry is slow to adopt, or even worse, they simply refuse to make changes until regulations mandate change. Simple economic drivers steer decision makers to the lowest-cost solutions to problems that are often designed to achieve minimum regulatory compliance. Sometimes it is hard to see the future, much less invest precious capital way ahead of the curve. The shipping industry is no different from any other industry in this way. We see the phenomenon playing out in the oil and gas industry as they wrestle with tailings ponds to treat or not to treat, whether to treat or dispose of fracking related flow-back water in disposal wells or recycle it for another use. Similar scenarios are playing out in agriculture, mining and food production and many more water industry segments. They all must have clean water to use in their processes, and yet they produce massive volumes of contaminated water. The solution is to cleanse wastewater for re-use with the lowest cost at highest impact.

Breakthrough Lowest Cost, Highest Impact Clean Water Technology Unveiled at University of Alberta

This massive business opportunity in the maritime industry comes at a time when water scarcity, as well as the global push to manage contaminated water, is at an all time high. At BioLargo we recognized quite some time ago that the key to solving the world’s water problems, including the maritime example, would require a new way of thinking about how to treat water, and that any viable solution had to be significantly less expensive than what historically was available.

Nature Shows the Way

Our company Founder and Chief Science Officer, Kenneth Reay Code, was certainly ahead of the curve when he set out to prove the theory that he could engineer a sustainable technical solution to create the lowest cost and highest impact sustainable clean water technology known. Having invested an entire career studying the natural Iodine cycle, his vision for the solution was clear and the mechanics of the natural iodine cycle could be his guide. The Iodine Cycle is simply an elegant cleansing system for our earth, and it is a critical cycle to maintain microbial balance in nature while, at the same time, iodine supports life as an essential nutrient and catalyst to oxygen Iodine is part of the circle of life, stored in the ocean, processed by phytoplankton and algae, evaporated into the clouds, activated by UV light, falls down onto the earth with the rain, as it is taken up by plants and animals on earth, and eventually finds its way back to the ocean. Our AOS Filter replicates and accelerates the mechanics of this natural cycle and enables us to generate extremely efficient cleansing and safely release the AOS treated water back into the ocean.

Just a few weeks ago University of Alberta researchers

unveiled the tested results of the BioLargo AOS Filter and explained the findings of 100 studies that demonstrate its potential to save the maritime industry billions of dollars per year as well its potential to impact just about every segment of the $350 billion water industry.

The AOS Filter combines iodine, water filter materials and electrolysis within a flow-through water filter device, generating extremely high oxidation potential that easily eliminates soluble organic contaminants and efficiently delivers extremely high rates of disinfection. The science behind the AOS Filter represents an astonishing discovery that will fundamentally change the way water is treated.

Remarkably, the BioLargo AOS Filter uses commonly understood materials and operates at ultra-low power levels. Its configuration essentially converts what would ordinarily be considered a typical filter into a safe and highly effective electrochemical reactor that generates extremely high levels of oxidation potential across the surfaces within the device. As a result, it can do the job at a fraction of the time and cost of any other known technology. Of course the bottom line is that it works, and it works so well that researchers call the results “unprecedented”.

BioLargo AOS Filter

Unprecedented advanced oxidation:

Unprecedented advanced oxidation:

Disinfects at less than 1/20th the energy cost of the nearest technical competitor, greater than 100 times the efficacy, and more than 10 times faster.

It is especially effective removing soluble organics like napthenic acids, 1,4 dioxane, benzene, and aeromatics. It also achieves extremely high rates of disinfection to eliminate bacteria, fungi and spores.

AOS Filter Capital Cost Savings

Our team at BioLargo has already assembled hundreds of AOS Filters from readily available parts as the company prepares for its first customer led commercial pilots. The cost to build one complete AOS Filter system is a fraction of today’s competing systems, and we expect our pricing model to be well received by industry. With an average cost of competing systems for use in the maritime market estimated at $750,000, we expect a substantial cost savings (both Cap-X and Op-X). BioLargo’s AOS Filter could save the maritime industry billions of dollars.

AOS Filter Operating Cost Comparison

In her thesis at Tallinn University,

“Advanced Oxidation Processes for Water Purification and Soil”, Anna Goi calculated the energy costs to operate UV and ozone technologies at varying pH levels to promote advanced oxidation and found that they can run in a wide range of anywhere from $100 per acre foot to as high as several thousand dollars per acre/foot. Energy cost for the AOS Filter in a high saline environment is less than 1/20

th the energy cost of the nearest competing technology.

To put this in perspective; a tanker carrying 25 million gallons of ballast water is the equivalent of about 75 acre/feet that has to be processed on each voyage before discharging back into the ocean. At the most conservative cost of $100 per acre/foot for energy costs alone, that equals close to $7,500 per trip. On the other hand, the AOS Filter uses so little energy that the energy cost to process 75 acre/feet at less than 1/20th would be in the $375 range or less, per voyage, versus $7,500 for the cheapest system. If a vessel with this much ballast water makes 30 voyages per year, operating costs for energy to power the AOS Filter would be less than $11,250 versus a minimum of $225,000 for competing systems. The energy savings alone leaves quite a bit of savings to help generate a rapid return on investment for the customer. The value propositions offered by the AOS Filter will enhance the payback even more quickly, but we prefer to keep those as a trade secret for today.

The AOS Filter can consistently generate complete disinfection/sterilization, and it is well suited to operate in high saline environments like seawater and other oil and gas industry related waters.

The AOS Filter Is Ready For Commercialization

With proven technology that is far advanced over all others, combined with low energy costs and competitive pricing, our AOS Filter is now ready for commercialization. BioLargo is positioned to be able to help maritime operators meet the stringent new requirements and at the same time save them billions of dollars. Discussions are underway with potential strategic alliance partners and customers. The next step is to engineer the unit to fit the customers’ needs.

Data from researchers conducting over 100 university studies show that the AOS Filter is the leading solution for the maritime industry as it offers superior efficacy and substantial savings. The AOS Filter has been shown to be so high impact and so low cost that it is expected to soon be pulled into almost every segment of the $350 billion dollar water treatment industry. We are pursuing a licensing and joint venture strategy to prepare for near-term commercialization.

Contamination of the oceans combined with troublesome worldwide pollution and global drought are all pointing to big global demand and a very bright future for BioLargo’s breakthrough technology. Our company is ready, willing, and able to bring high value to the maritime industry as well as many other industries and to become a remarkable commercial success in the short, medium and long term.

This article was brought to you by BioLargo. BioLargo, Inc. designs and delivers nature’s disinfectant iodine. Its technologies include AOS Filter, CupriDyne, and Isan system.

Mnemiopsis leidyi, a comb jelly (similar to a jellyfish) feeds on anything smaller than itself that gets stuck to the sticky lobes near its mouth, especially zooplankton. It was probably introduced via ballast water from New England (USA) into the Black Sea. In its new environment, Mnemiopsis has no natural predators and has outcompeted native species for food. As a consequence, the once profitable anchovy fisheries in Russia and Turkey have almost disappeared.

Mnemiopsis leidyi, a comb jelly (similar to a jellyfish) feeds on anything smaller than itself that gets stuck to the sticky lobes near its mouth, especially zooplankton. It was probably introduced via ballast water from New England (USA) into the Black Sea. In its new environment, Mnemiopsis has no natural predators and has outcompeted native species for food. As a consequence, the once profitable anchovy fisheries in Russia and Turkey have almost disappeared. One of the most widely known invasions in the United States is that of

One of the most widely known invasions in the United States is that of

Unprecedented advanced oxidation:

Unprecedented advanced oxidation: